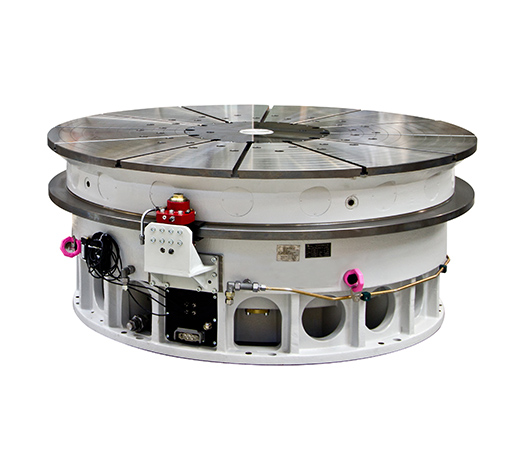

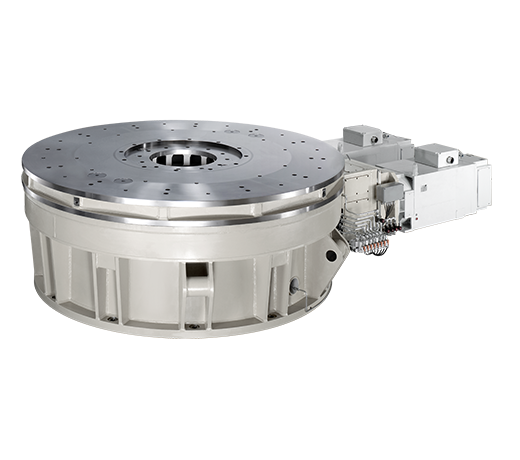

ZOLLERN develops and produces high quality rotary table systems for the areas of milling, turning, grinding and measuring. Whether a proven standard or individual special solution, each of the different rotary table series convinces with its high machining quality and economic efficiency. They all have the most exact positioning and a high concentricity and axial runout accuracy in common.

ZOLLERN offers comprehensive service for rotary tables of the brands ZOLLERN, Rückle and Eimeldingen.

Service for rotary tables of the brands ZOLLERN, Rückle and Eimeldingen

ZOLLERN offers quick spare parts deliveries, technical findings with repair report, repairs, assembly work worldwide and commissioning support for all rotary tables of the brands ZOLLERN, Rückle and Eimeldingen.

- Original spare parts

- Retrofitting, revision and repair

- Sales force

- Error analysis on site

- Maintenance service

- Commissioning on site

- ZOLLERN training centre

- Diagnostics and condition monitoring

- 24/7 support, service hotline