Welcome to ZOLLERN!

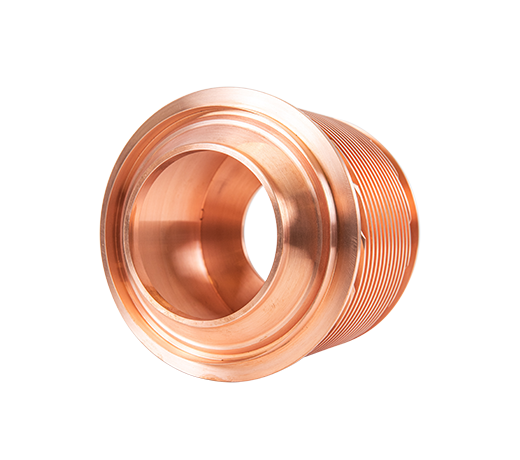

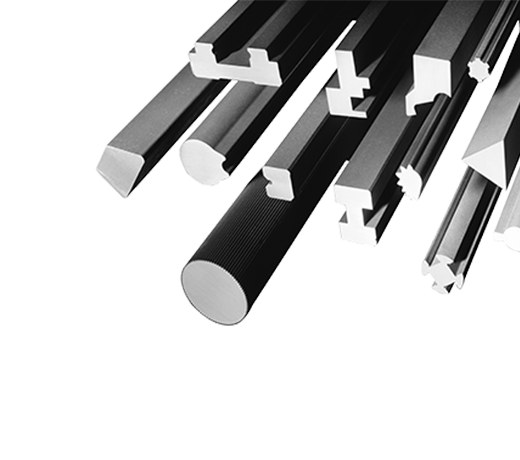

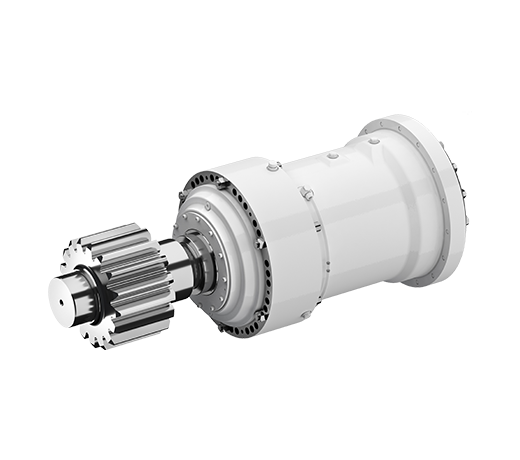

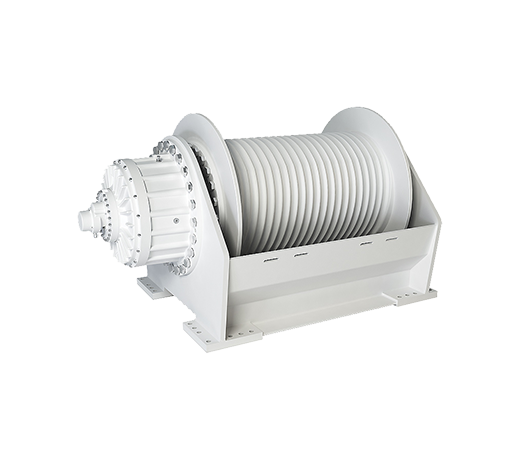

ZOLLERN offers customer-specific products and technical solutions for challenging applications. Every component, every module and every solution has special expertise and perfection in it.

Developers, designing engineers, materials experts and application engineers together ensure that the products and solutions always meet customer-specific requirements.

ZOLLERN stands for the highest level of quality - for more than 300 years.