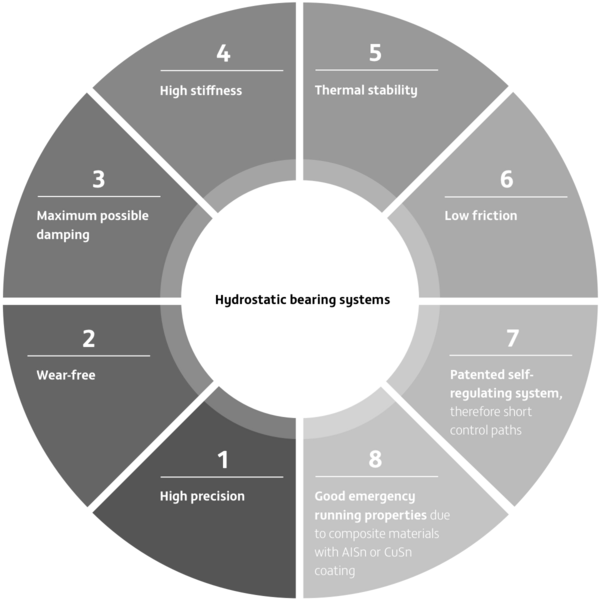

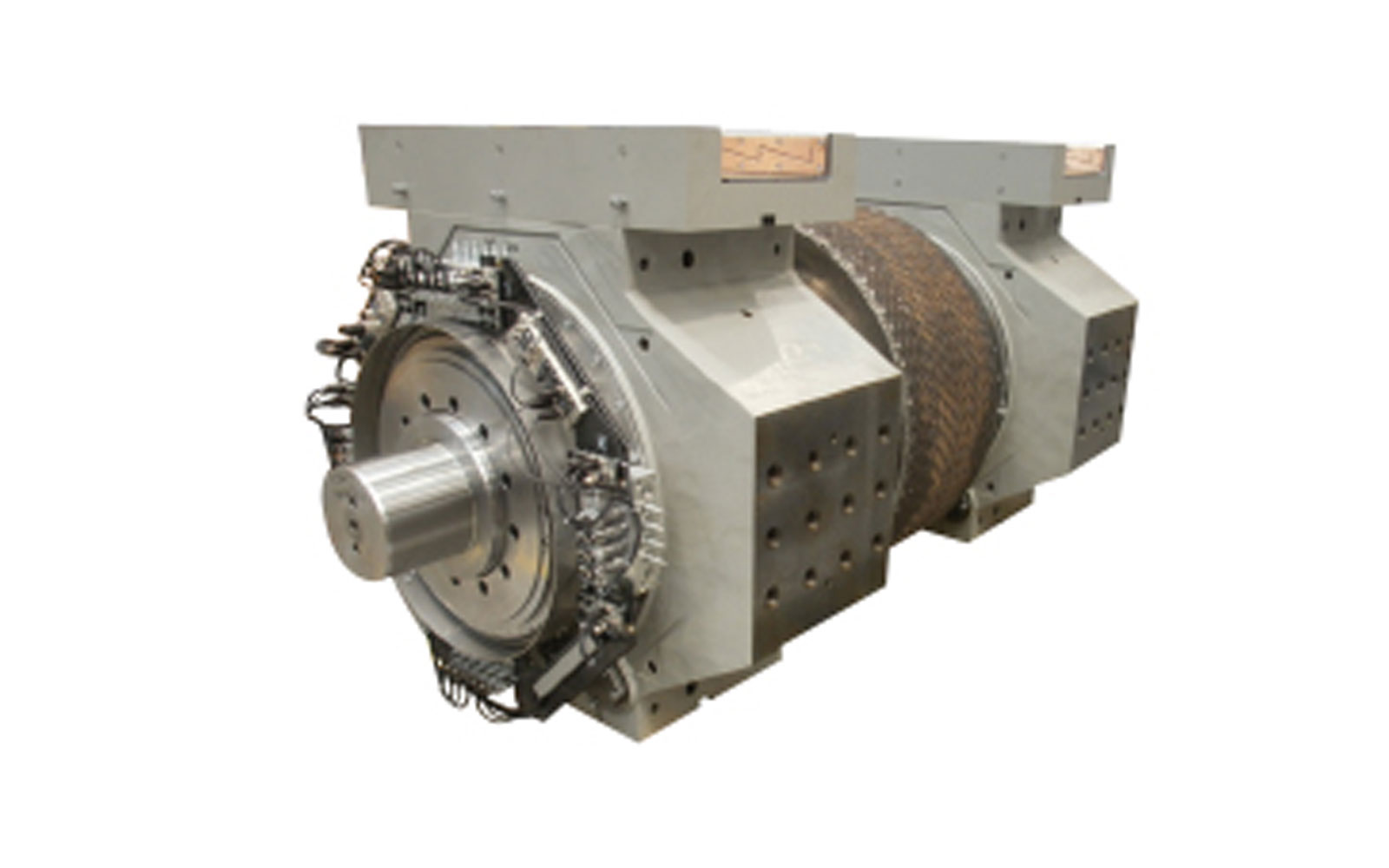

Hydrostatic bearing systems – wear-free, precise, with high running smoothness

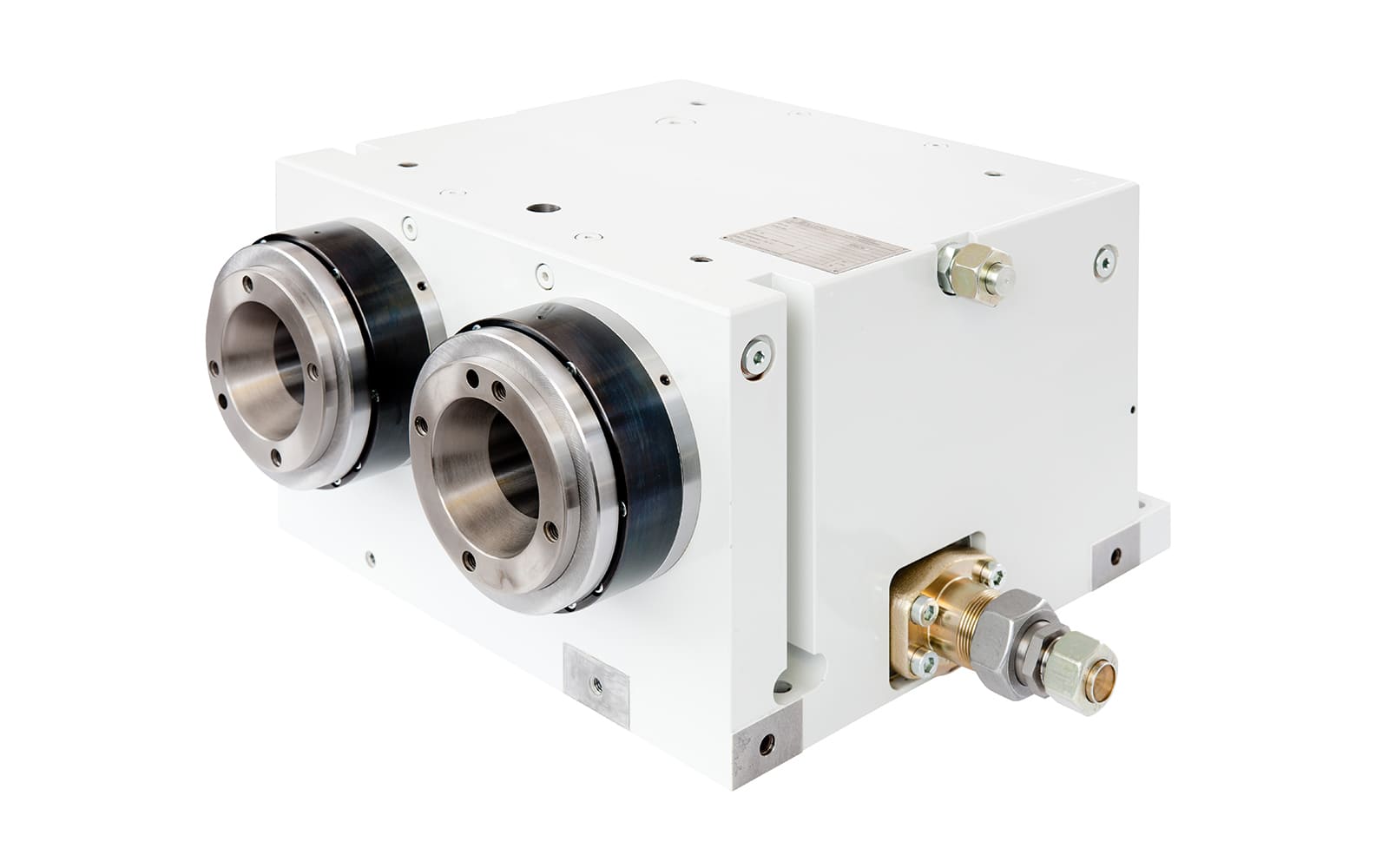

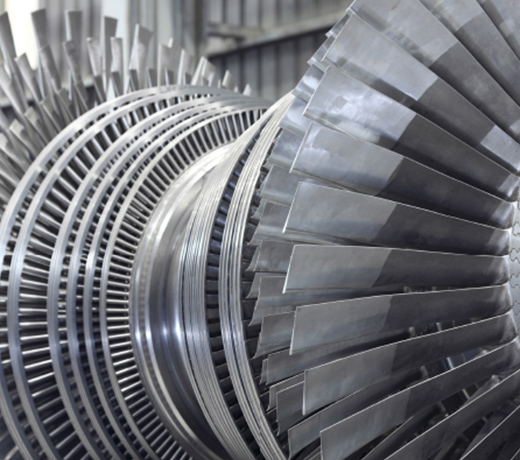

ZOLLERN offers hydrostatically mounted spindles, rotary tables, guides and bearing components for applications where freedom from wear, a high level of precision and running smoothness are required.

For hydrostatic bearings, moving parts and housing are separated from each other by an oil film, independent of the load or sliding speed. There is no direct contact. Sliding bodies or the like are not used.

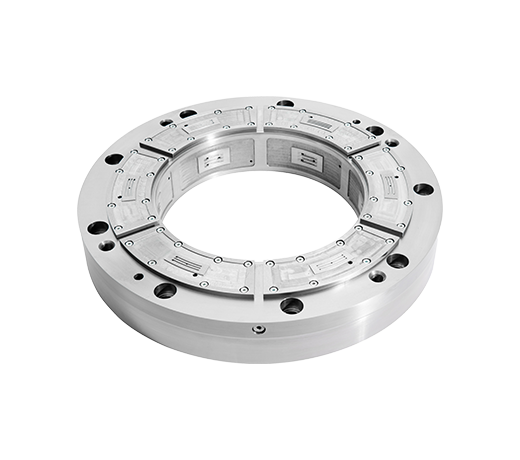

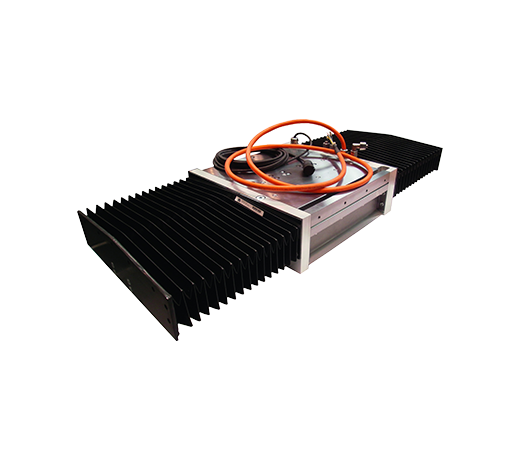

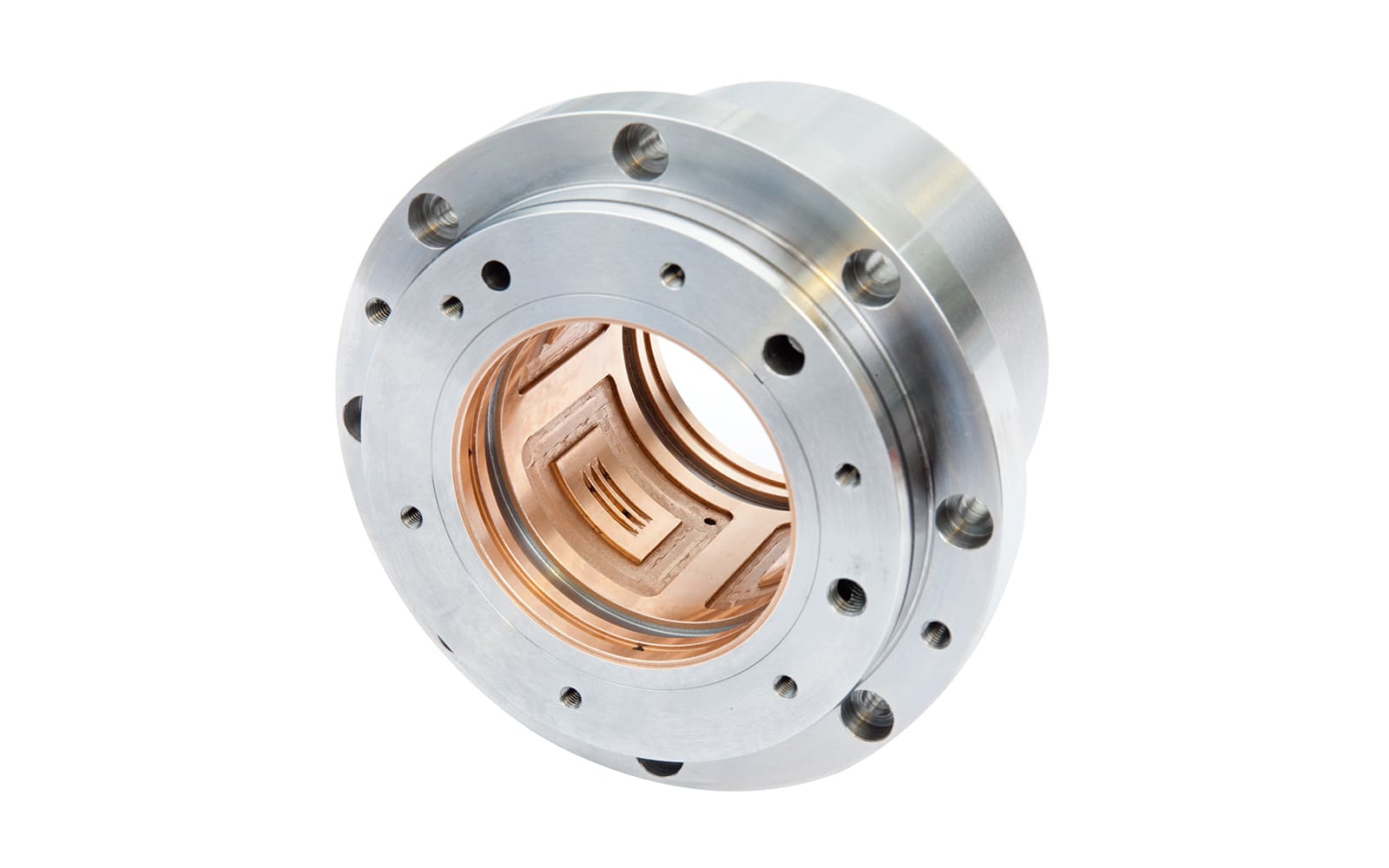

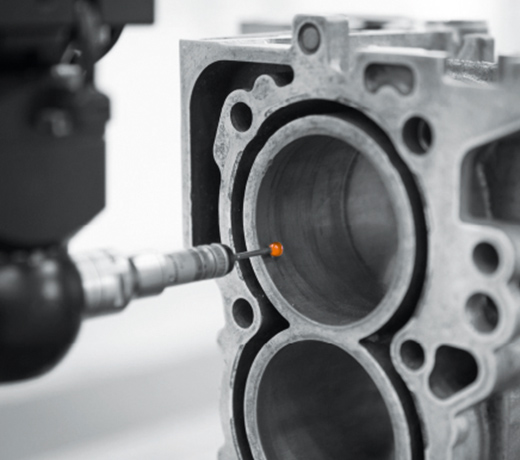

Unique restrictor system

With the ZOLLERN running clearance throttle, ZOLLERN has developed a unique and variable restrictor system, which is directly integrated into the hydrostatic bearing. External regulators, capillaries, hydraulic orifices or multiple pump circuits, as required by other hydrostatic bearing systems, are not required. In addition, there is no need to adjust the throttle system during commissioning. The optimal pocket pressure is therefore always set, regardless of the production tolerances.

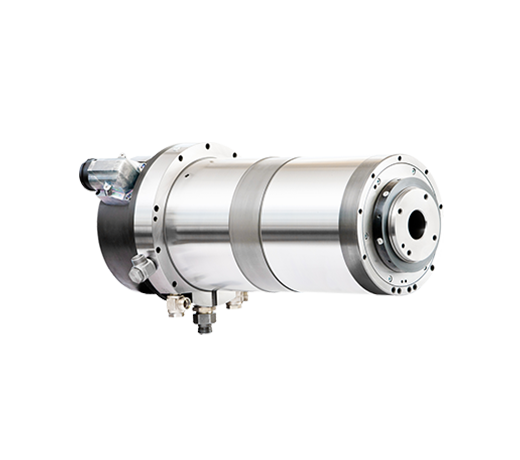

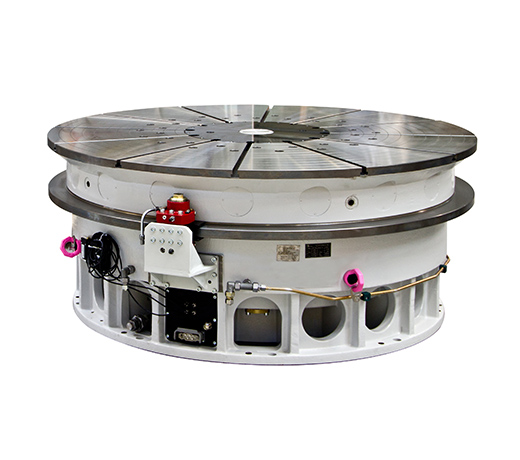

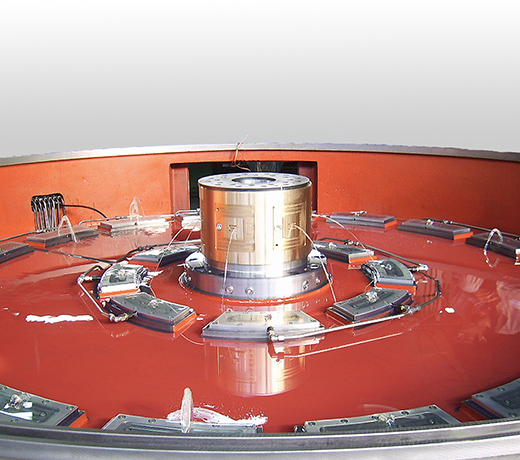

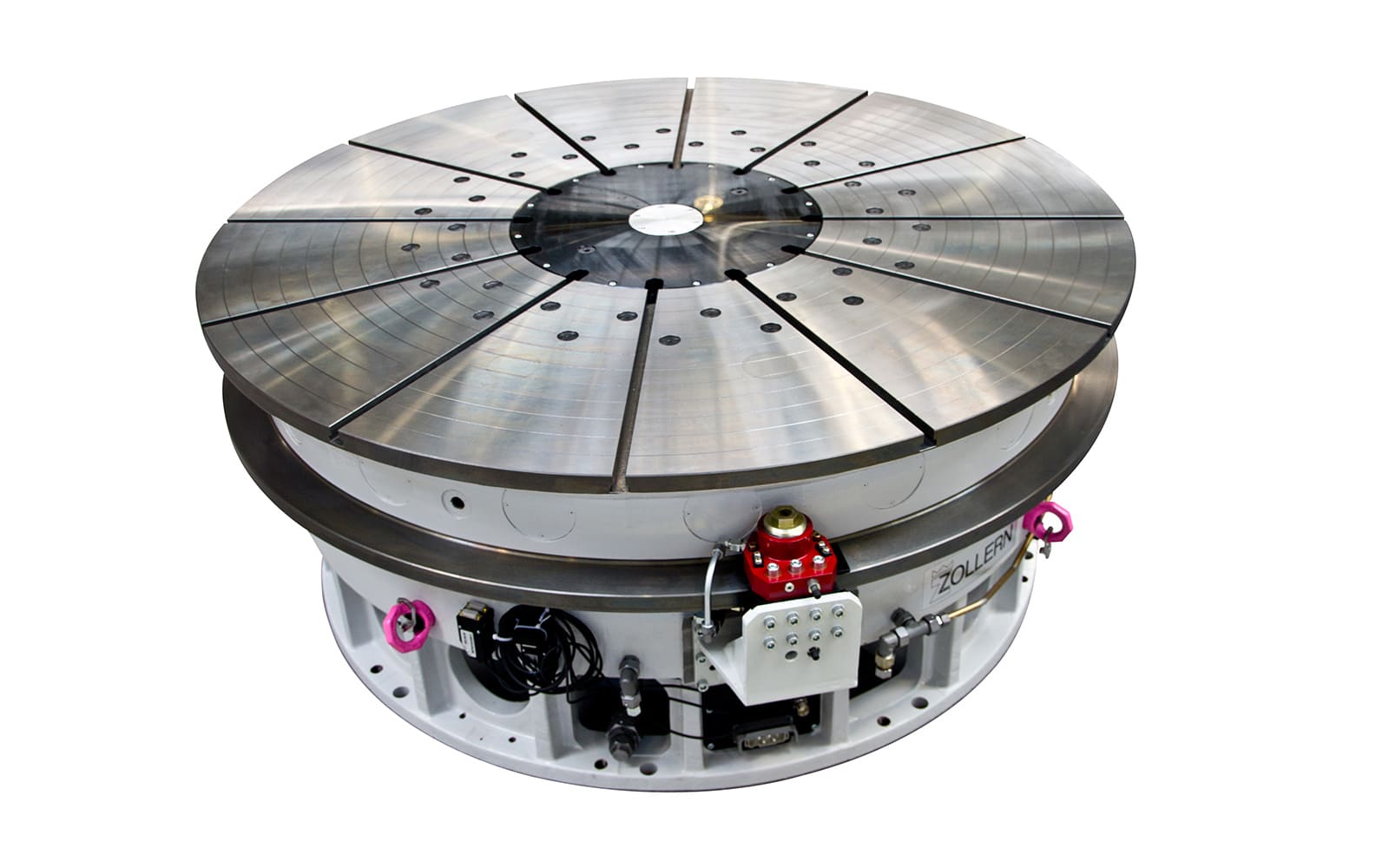

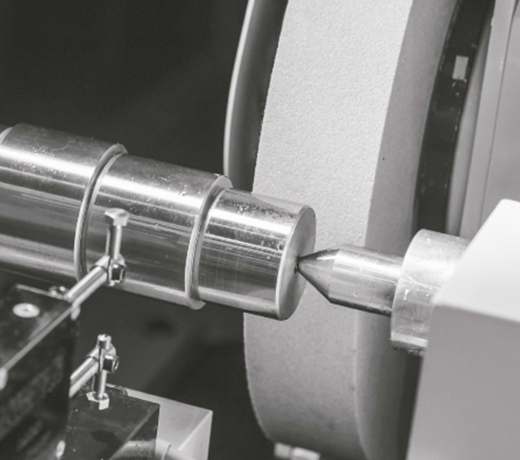

Turning machines

Hydrostatic workpiece spindles, rotary tables, rotary axes for tool turrets or bearing components for the area of hard turning

- Very good damping properties

- Very good concentricity and axial runout accuracy

- Very high positioning accuracy

- High achievable surface quality

- Thermally stable

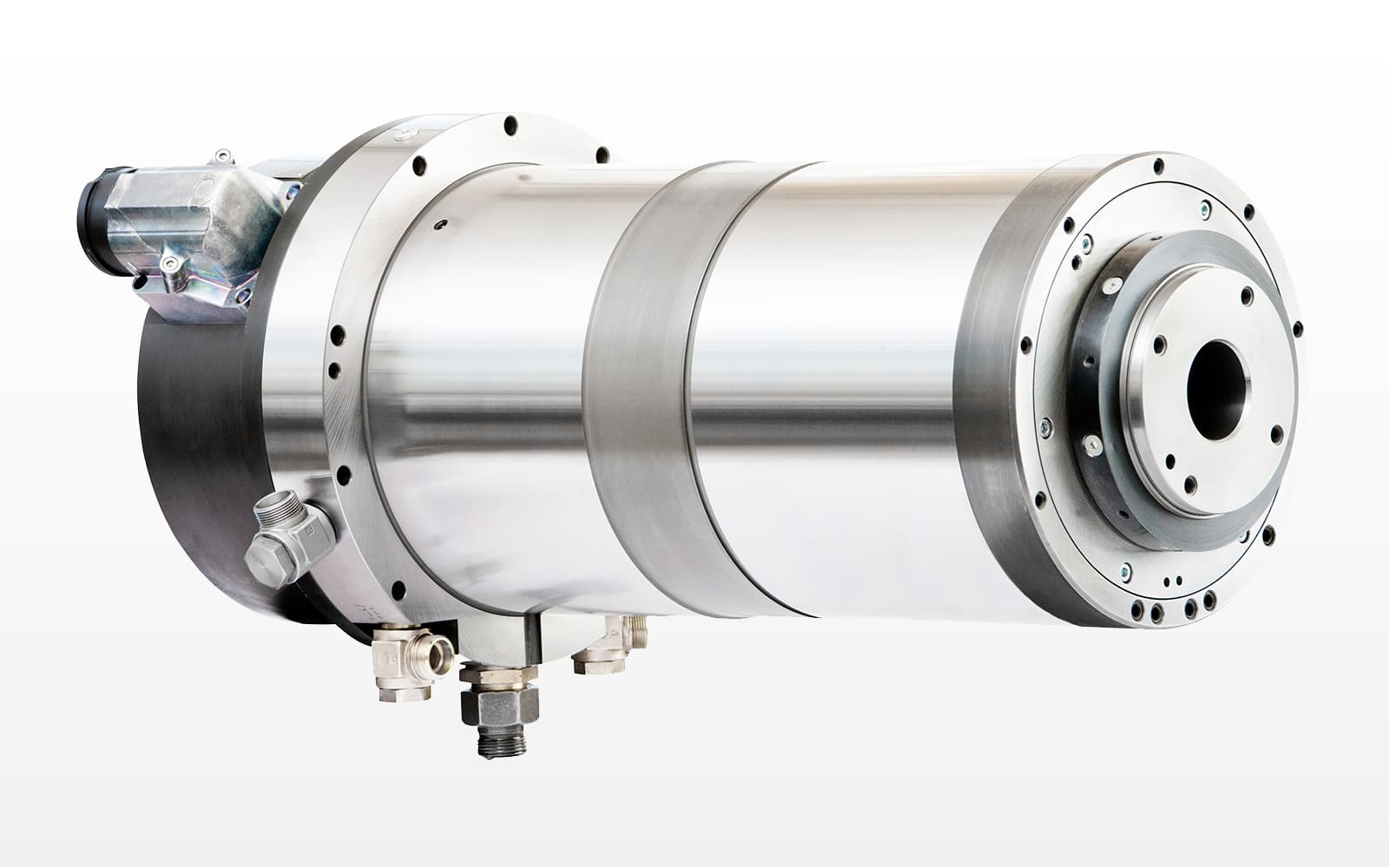

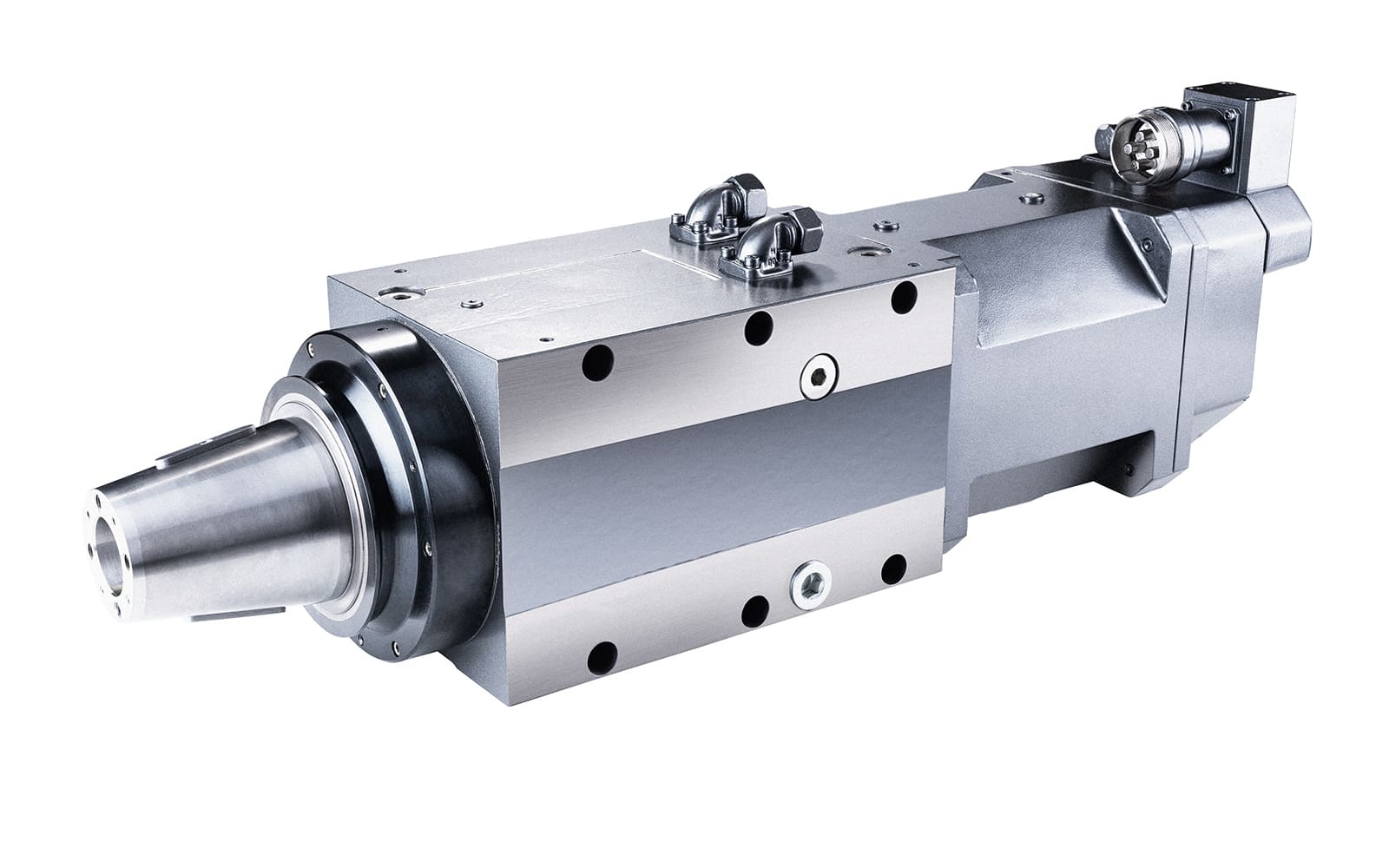

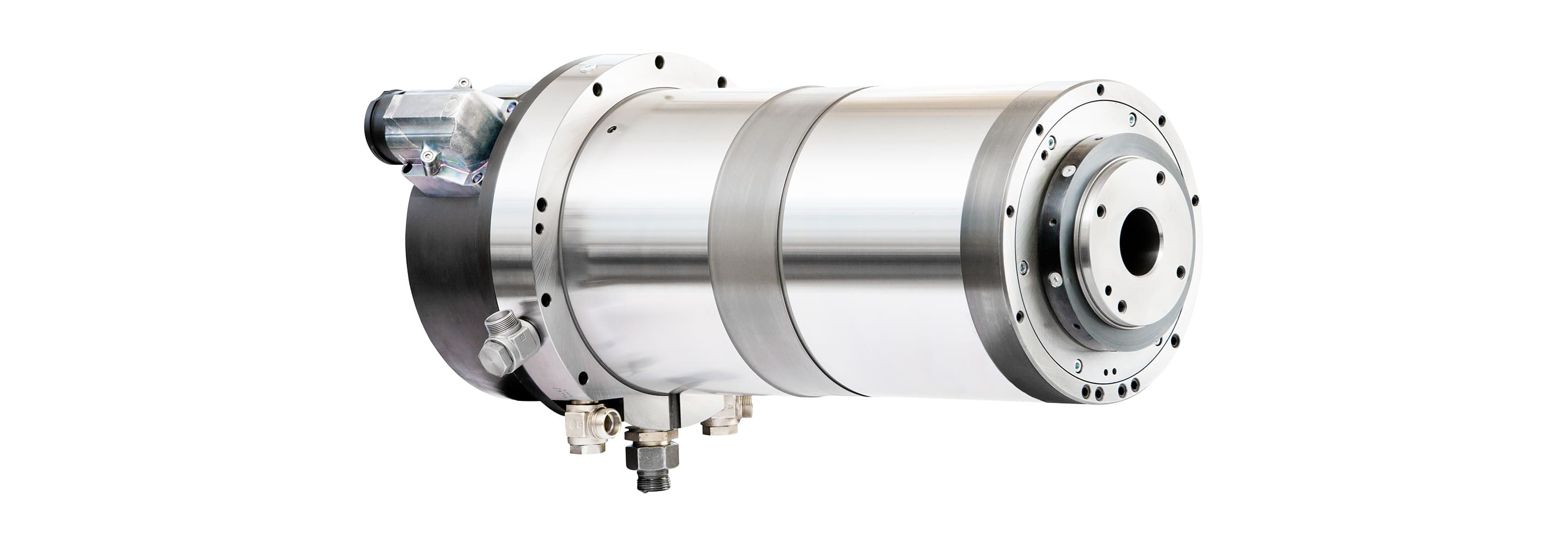

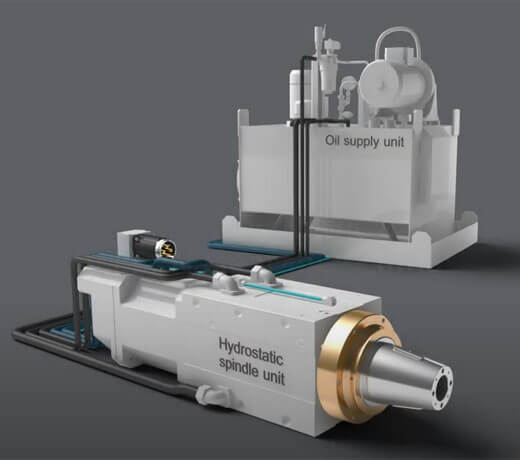

Hydrostatic spindle unit with ZOLLERN clearance compensator

The ZOLLERN clearance compensator ensures optimum pocket pressure in the spindle unit. It is integrated into the fully hydrostatic bearing part of the spindle and the optimum pocket pressure is automatically set within the manufacturing tolerances. The patented clearance compensator is a self-regulating system with fast control behaviour and high rigidity. It is used in spindles as well as in hydrostatic rotary tables and linear guides.

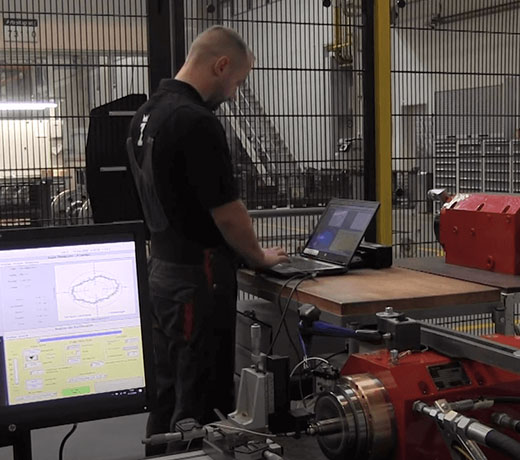

ZOLLERN customer service offers fast spare parts deliveries, technical findings with repair report, high quality repairs by the manufacturer, assembly work worldwide, and commissioning support.

- Original spare parts

- Retrofitting, revision and repair

- Sales force

- Error analysis on site

- Maintenance service

- Commissioning on site

- ZOLLERN training centre

- Diagnostics and condition monitoring

- 24/7 support, service hotline